Accredited 2015-2018 Universal-Robots support Centre and Forum. MiR Service & Support Centre.

Home | About | Products | Case Stories | Applications | Control | Service | Contact

Singapore

info@zacobria.com | Sitemap | AP map | Disclaimer

Zacobria Profile Singapore.

Zacobria Pte. Ltd. is based in Singapore and focus on support to industrial automotion and robotics.

Zacobria Pte Ltd and our sister company Esmap Services Pte Ltd are established by Lars Skovsgaard in Singapore who have 40 years of experience in Electronics and Automation as follows:

8 years of working experience at LEGO Systems IT department as electronic engineer.

10 years at Crisplant A/S, a provider of high speed automation solutions used world wide commonly at airport baggage handling systems.

Since 2002 permanently based in Singapore with the Asia Pacific region as working area serving companies such as:

Crisplant Beumer.

Universal-Robots (UR).

Mobile-Industrial-Robots (MiR).

Robotiq.

Vetec (Nordtech) Weighing Solutions.

Work Experience:

40 years experience in component level support

30 years automation experience

20 years permanent based in Asia pacific

10 years Robotics experience

Business experience

Director and Business owner

Sales PL and accounting

Contract negotiations MNC and GLC

Customer Support

Role experience

Service Manager Project Manager

Technical Supporter

24/7 Hotline Supporter (WW)

Commissioning engineer

Field Service engineer

Training performer

Technology experience

Electronic circuits, Computers, Microcontrollers

Data Communication RS-485 USB

MODBUS TCP

Ethernet TCP/IP

System Platform experience

Linux Ubuntu

Windows & MS Office

Jira

Programming experience

Python

ReST API & Postman

Robot arm programming

AMR Mobile Robot programming

HTML and Web design

Product experience

Universal-Robots (UR)

Mobile-Industrial-Robots (MiR)

Vetec

London Electrics

Sick

3D cameras and vision systems

Sensors

Segment experience

Robotics Automation

Autonomous Mobile Robots

Loadcells

Displays

Wireless Radio Communication

Lidar Laser scanner

3D cameras Camera and vision systems

Sensors Photo & Proximity sensors etc.

Countries served

Singapore Korea Japan China Malaysia Indonesia Thailand Vietnam Taiwan Philippines Australia New Zealand India

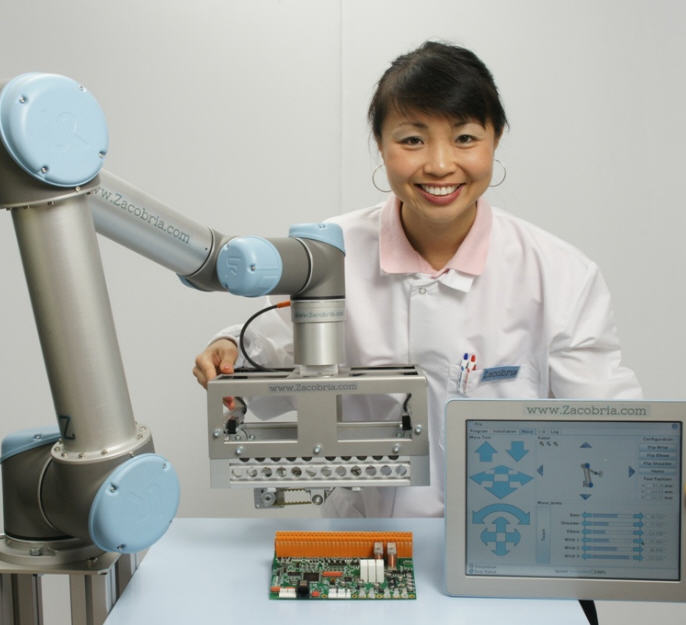

Obtain an ROI (return on investment) within 1 year through the utilisation of a Universal robot arm and automation from Zacobria.

Singapore encourages local-based companies to create mechanised and automated work environments to keep a highly educated and skilled workforce as well as workplaces for it in Singapore.

Efforts to this purpose have been made by way of tax policies that benefit local companies who introduce mechanisation and automation, and by way of allowing accelerated capital allowance for most assets used for business purposes.

The Productivity and Innovation Credit (PIC) scheme has been introduced in the Singapore Budget to encourage productivity and innovation, by providing enhanced tax incentives for investments in a wide range of activities, such as automation equipment and training of employees.

Encouraging productivity and innovation.

The Singapore Productivity and Innovation Credit (PIC) scheme offers a 400% tax deduction on up to 400,000 SGD of your investment, or a cash payout option of up to 30% of your 100,000 SGD investment.

Lab Automation.

Laboratory processes are suited for robotic automation as the processes are composed of repetitive movements (e.g. pick/place, shaking, and testing).

Automation and robotics are increasingly freeing scientists from the need to constantly monitor their experiments. Introducing automation increases productivity, reduces laboratory costs, and provides individual researchers with more time for creative purposes.

Researchers are making steady progress, advancing their science with new tools and systems that can prepare samples and run experiments.

Automation of routine laboratory procedures and fully functional robotic systems can turn jobs once done manually during an eight-hour shift into procedures that require very little human intervention, and that operate (at least in theory) 24 hours a day, 7 days a week, 365 days a year. Simple, repetitive tasks can be automated.

Free uptime for workers.

Automation and the ever increasing number of robotics have transformed the typical workday for many individual workers.

Advantages using Industrial Robots.

Faster processing (notice that automation is not always faster than a human operator)

Increased repeatability

Increased productivity

Improved efficiency

High reproducibility

Establish safer working environments

Reduction in materials wastage due to optimised process variables

Ability to perform work continuously unaffected by human constraints

Ability to perform work in and around harsh environments

Withdraws staff from monotonous, repetitive tasks

Author:

By Zacobria Lars Skovsgaard

Accredited 2015-2018 Universal Robots support Centre and Forum.

Mir Mobile-Industrial-Robots Service and Support Centre.

Home | About | Products | Case Stories | Applications | Control | Service | Contact